Search the Community

Showing results for tags 'tr4'.

-

Hi all, I am thinking of doing something different with the rear seat, it would seem its only function would be as a hood frame receptacle. As mine didn't come with any trim anyway I thought I would do something practical in this area, I know it wont be authentic but I would like some ideas of what could be done, with photos if anybody has got any. Regards Ron

-

If anyone is interested, I can put you in touch with the current owner of a set of perfect condition but used 92mm pistons, liners and standard length h beam con rods. The rods have big end size for a steel crank. I think that this is likely to be Ford cosworth dimensions. I have yet to establish a price for these from the owner, but I suspect it’s all going to be a bit of a bargain if it’s your bag. These have been removed from an engine that needs to go to 87mm due to regulations. David

-

If anyone is interested, I can put you in touch with the current owner of a set of perfect condition but used 92mm pistons, liners and standard length h beam con rods. The rods have big end size for a steel crank. I think that this is likely to be Ford cosworth dimensions. I have yet to establish a price for these from the owner, but I suspect it’s all going to be a bit of a bargain if it’s your bag. These have been removed from an engine that needs to go to 87mm due to regulations. David

-

Hi all, I need to replace 1 outrigger on my TR4 does anybody know the correct gauge and size and suppliers if possible ? Regards Ron

-

Hi all, I need to replace 2 pushrod tubes on a TR4 head which have rusted through, are they pressed in or are they just pushed in and flared to seal ?. I am preparing the head for unleaded conversion and so I have complete access. Regards and seasons greetings Ron

-

Seeking a small diameter hub boss. My TR2 steering column has a splined end that the steering wheel hub fits onto. Do later TR models like TR4, TR5 have the same splined end of the steering column? I need to buy an aftermarket hub boss that fits those splines, in order to fit a restored specialty steering wheel for my Doretti (using same TR2 column). But I don’t want to use the large diameter boss that is available from Moss to fit a Moto-Lita wheel to a sidescreen TR - because I have a smaller wheel center that is more like TR4. Wheel is pictured. So if I buy an aftermarket TR4 hub boss, might the splines fit my TR2 style Doretti column? Dan

-

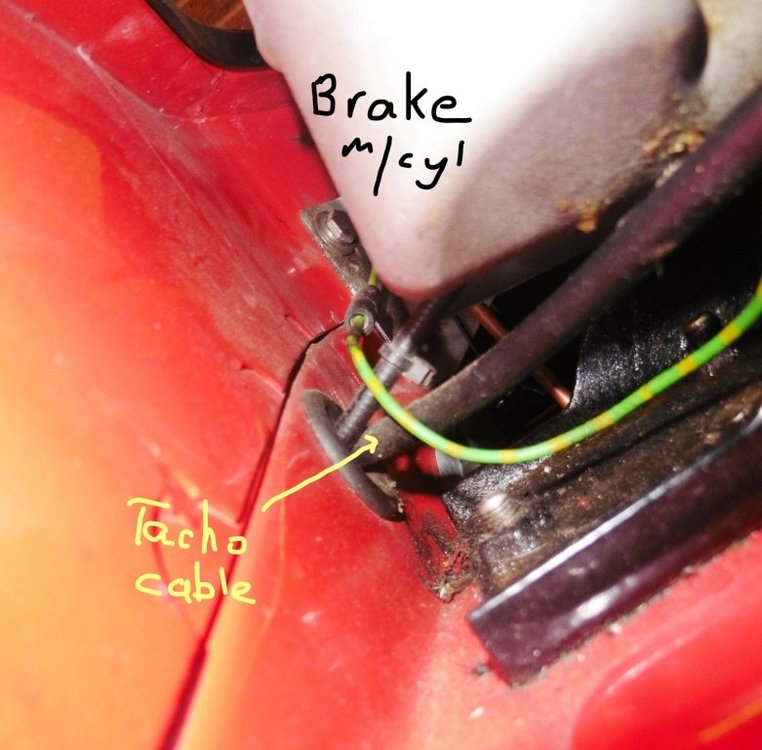

Hi All, I would appreciate feedback on whether or not my tacho cable is fed the wrong side of the master cylinders bracket and, whether the cable is too long. A few photos attached to illustrate. If too long, where do I obtain the correct length? Best wishes Willie

-

Hi all, I'm pondering hood storage in the boot, my thoughts are either place the hood on the spare tyre and the cover it with a suitable piece of plywood on a couple of runners to stop pressure damage or some sort of plywood lid attached to the boot frame. Has anybody done this ? any thoughts, advice or photos would be helpful. Regards Ron

-

Hi all, I am putting together an emergency toolkit for my 1962 TR4 . I will include the usual set of spanners, an adjustable spanner, hammer, gaffer tape, screwdrivers, pliers, length of wire, points, condenser,feeler gauges and torch. Is there anything you can think of that I might need, something that you've stood by the roadside thinking "I wish I would have brought that" Please don't include welder,compressor,engine lift or competent mechanic etc. as they would be too big for the bag Regards Ron

-

Hi All, My TR4 temp at the thermostat housing is about 82c when measured with an infra red thermometer but the head temp is higher at about 112c . Is this normal ? Regards Ron

-

Hi May I beg a rather ignorant question - I presume that to replace an axle oil seal (ie: the one at brake drum end) a Hub Puller is required?? My '4 has been quietly leaking oil onto the nearside rear brakes during its 5+ year snooze, and before that I seem to recall. Assuming the answer is "yes, obviously", and presuming I can lay my hands on said puller, should I: (A) Do both sides (yes, obviously?) (B) Replace the wheen bearings (yes, obviously?) Thanks. Adrian + TR4

-

Hi all, after putting off the hood fitting for ages I finally decided to do it today as the weather has warmed up, I have read a lot of items regarding the fitting process and I could forsee the problems and the chance of having a hood sagging or with ripples in it so not a task for the faint of heart ( hence the delay ) I also had a sore thumb the result of a very close encounter with a hammer head ! and so I was dubious about my ability to pull the hood tight to get the correct fit as it looked about 6 inches short So I had another coffee and a think, I decided to reverse the hinge bracket on the B post and use them on opposite sides which meant the hood sat down about 1 1/2 lower. After letting the hood warm in the sun I then marked and cut the first fitting, the lowered hood allowing me to easily stretch and mark the position ( I was more nervous than when my kids were born ) I also realised this method would only be good for the rear fittings parallel to the screen. Having done all the back ones I then switched the hinges back and erected the hood, big relief when it all looked good. Because the hood was now in tension the sides were relatively easy to position. Conclusions Spend lots of time centering the hood with chalk marks etc. Mark and fit each fitting one at a time, I had a big log end on the rear seat to act as an anvil. I found the punch off ebay was too clumsy too get a consistent fitting so I used a hole punch and then aligned the fitting punch on the hole and parallel to the edge, I also had to sharpen the spikes to aid the cutting. I bought the hood from Don Trimming and it was well cut for the job ( although the first time I tried it on I thought it was too short ) I hope this helps as I know I was anxious about the finish which if done incorrectly would attract the eye immediately. Regards Ron

-

Evening all, My TR4 suffered a slightly bewildering electrical fault on the way home from work this evening. Bear with me, I have some questions at the end... I'd just joined a fairly fast B road when there was a small clunk and then the sound of an electric motor running at high revs. My first thought was that my Kenlow fan had come off the motor! Very odd I thought. There was nowhere to stop so I carried on for a bit. I then glanced at the ammeter and saw that it was pinned at about +30A. Still not able to stop I switched the ignition off and then back on again, which stopped it. It then happened again a very short while later but luckily I was able to pull over. I stopped the engine and noticed that the key was bit warm as was the starter solenoid. I started the engine and it was clear what the problem was - the starter motor continued to run when the key was released. I pulled the wire off the starter solenoid and this sorted it out until I got home. So, I've just been in the garage running a few tests. There's clearly a fault in the ignition switch. With the ignition on, there's about 13 ohms between the starter terminal on the switch and +ve on the battery. This drops to zero when the key is turned to start. Therefore, the starter solenoid is powered to a degree all the time. Now interestingly, this 13 ohms means that there is not quite enough juice to pull in the starter solenoid but there is enough to hold it in. So how did it manage to engage while I was driving? Perhaps a bump in the road was enough to jolt the solenoid closed, who knows. Anyway, I'm relieved that nothing appears to have been damaged and I didn't melt the starter. Anyway, as promised, here are the questions: Is it worth trying to repair the ignition switch? If not, there are plenty out there, some Lucas branded others not. Any recommendations? Is it possible to swap the lock barrel from my current switch into a new one? On a scale of 1 to Brexit, how difficult is this to do? Cheers, Steve

-

Hi all, I have decided to paint my TR4 Velasquez cream but as it is a complete colour change I have no parts for the paint supplier to match, they tried on their system but it gave no results Does anybody know where I could get a swatch of this paint or failing that has anybody got some that they could put on a piece of card and send to me, or is there another paint colour that is a near match ? Regards Ron

-

Hi all, could someone tell me what size screws are used to fix the webbing plates to the hood sticks please. I put them safely away and ( as usual) can't find them. Are they threaded screws or self tappers ? Regards Ron

-

Hi all, I am preparing the chassis for my next TR4 rebuild, I want to check the rear end where time and gravity tends to make it drop. I have it on a flat surface which I know to be true and I want to measure the height above the surface of the very end of the chassis. has anyone got this measurement ? I have the workshop manual but it is not clear to me. Regards Ron

-

Hi all, My temp gauge starts off in the cold position and as the engine warms it starts to move, so far so good, but it continues all the way to 120c. The actual temp at the thermostat housing is 85c . It is a new sender unit. Any ideas from the sages Regards Ron

-

Hi all, I have a question about my gearbox from my TR4 (1962). Does anyone know why my gearbox is harder to switch in hot weather? It's harder to get into gear. Sometimes from three to four a little crack. Not Always. Just that it's not completely synced. In the spring I never had this before. And only if he's been riding hot. The next day everything is back to normal

-

Hi All, Rebuilding a 64 TR4 (LHD US import) here, and I've had a good look through the forum, but I can't find the specific details I'm after to carry out the LHD to RHD conversions. I've rebuilt the Chassis, Diff Gearbox and Engine, but the body shell is still in storage and I can't get access to it for another few weeks.. I've changed out the steering rack with no particular drama so far, but I'm trying to find out if all or even some of the steering column bracket mounting points are present on the internal face of the firewall to relocate the steering from LHD to RHD, or whether I'll have to weld in new brackets or anything structural. Does anyone have a pattern or graphic layout showing the size and location of the cutouts and penetrations on the RH firewall and scuttle panels? Best regards Pete

-

Just thought I would share some information regarding voltage stabilisers. Both Moss and Rimmers specify the part number 128484 for both TR4 and TR4A. However this stabiliser is for positive earth only vehicles (i.e. original TR4 spec). As such they will not work on the TR4A. Instead you should fit the TR5 unit part number 148876A which is for negative earth cars (TR4A and later). This is because these later units have solid state internals and need to be connected with correct polarity. The original stabilisers had a bimetal strip with a heating wire coiled around it. Voltage was regulated by the rapid make and break of the bimetal strip. Didn't matter whether positive or negative earth for those types. Would work either way. Earlier Moss solid state units had part numbers 131-555 for negative earth and 131-556 for positive earth if you have one of those. This all came to light this morning when I turned out the spares in the boot to find that my spare voltage stabiliser was a positive earth rather than negative for my 4A. Also discovered the spare spark plugs had gone rusty and were not the same as in the car and the spare radiator cap had disintegrated. Time for a spares spring clean I think to see what other junk I have been driving around with in the boot. Keith

-

I need to raise the drivers door on my TR4A by 2-3mm. The manual suggests this can be done by releasing the bolts on the hinge (3 bolts per hinge) Any suggestions on how to do this, particularly how to hold the door in place when I release the bolts.

-

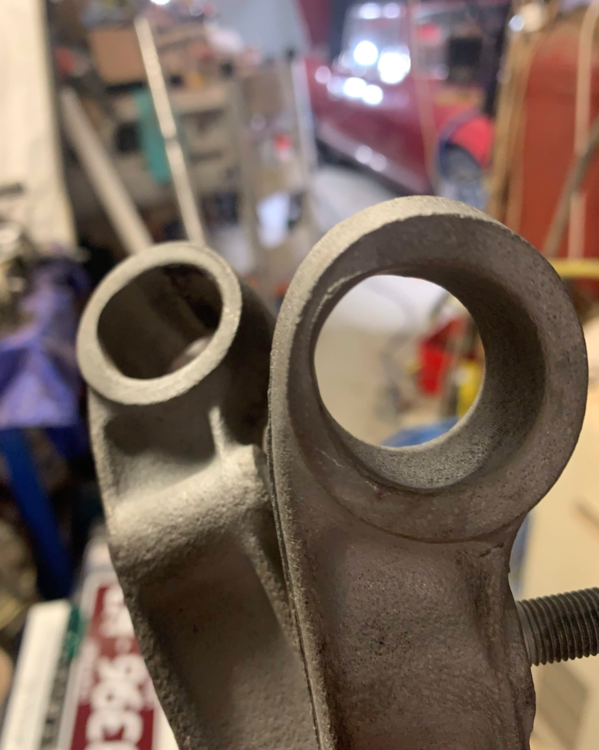

Hi all, Just hoping to get some advice from some of the more experienced members here as to whether it is possible - or advisable - to have TR4 lower control arms welded up by a competent welder. The arms on both sides have out-of-round holes where the bearings have worn through, and these are very hard to find in Australia, and the ones which pop up on various sites often seem to be in worse condition than mine anyway..so refurbishment by welding, drilling and reaming is probably going to be easier than replacement. Has anyone done it, or had it done, or seen or heard of any catastrophic failures resulting from this? IMG_6296.HEIC IMG_6301.HEIC Best regards Pete

- 1 reply

-

- refurbishment

- welding

-

(and 2 more)

Tagged with:

-

I have rubbed the casing flange to bare metal where the parts book indicates the number is, but there is nothing there! Can anyone advise where I will find it? All that is on the casing near the vent is TC2 [in upside down position!] Yours hopefully Willie

-

My current task has been to fit a new windscreen & glazing rubber - not a massive problem, done a couple before & have the help of number two son who is isolating at home. In anticipation of doing the work I bought a new seal from TR shop as I thought the old one may be a bit hard by now. Tried to fit it to the screen with a squirt of soapy water the same as always and found I had what can best be described as several inches too much to fit! - The profile looks absolutely correct but there isn't a hope in hell it's going on this screen. I cleaned of the old one & ten minutes later - job done & fitted, shouldn't have bought the new one.... Anyone else encountered this issue?

-

Hi, My TR4 has the conventional set up of a wide fan belt and lucas dynamo. The dynamo cannot swing enough towards the engine to allow the belt to become clear of the dynamo pulley so as to remove and refit. Is this how it should be and the procedure then is to remove the dynamo pulley or water pump pulley to allow the removal/fitting of the belt? Thanks Andy