Search the Community

Showing results for tags 'gearbox'.

-

Hi Folks, I found the filter magnet in the Overdrive in four pieces the other day. So today I bought a new magnet(s) only to find it is slightly different. The new magnet is made up of three fairly thin rings. The original was one thickish ring. All three rings togther are slightly thicker than the original; However using just two rings it is slightly thinner than original. What have people used as the norm? - three rings or two rings. Roger

-

Morning all, I suspect a quick question, is it possible to remove the overdrive without taking the the gearbox out? Appreciate gearbox will need to be supported, but is there enough room given the length of gearbox mainshaft. Thanks

-

Hi I am in the process of fitting the later 4a diaphragm clutch to an earlier 4 'box. I have had the flywheel redrilled, lightened a little, balanced and returned to me with a new clutch plate, cover and bearing. I am advised that I need the later bearing carrier for the later bearing, which makes sense. However, by chance I have spotted a sentence in an old Moss catalogue that reads (part 100157) "TR2 to TR4 models were originally fitted with a 2 3/8 inch front cover extension. These must never be used on vehicles with diaphragm clutches. Shorten accordingly" and there is another note that mentions a 2 inch sleeve. What happens if the extension (item 8 in the diagram) isn't shortened as stated? So shorten to 2 inches? Any other pitfalls? Thanks, Adrian

-

Hi, I’d appreciate some advice on my 1970 TR6 clutch problems.......... I rebuilt my TR6 over lockdown. ‘New’ chassis and body, swapping the engine and box over from one chassis to the other without doing anything major to them because they were working perfectly, and they have been undisturbed for at least 24 years with fairly limited mileage. My first big drive was to Malvern last year when I found getting into 2nd gear difficult, especially going down from 3rd . Since then it has been getting progressively worse, to the point where it is no fun driving it. I’ve tried a few fixes but no joy. The symptoms are: · Engine off I can get all the gears. Not Ford smooth, but doable. · Starting from cold, gears are gettable, but reverse grinds horribly. · As the car warms up it becomes harder and harder to find all gears, especially 1st and 2nd and reverse but then I get nasty grinding on 3rd. Double declutching and slowing the engine revs can help, but not always. · Eventually I have to force it into 1st or 2nd to get going, and that isn’t easy. One day I really will get stuck at a junction. Quite stressful. · If I am stationary and get it into gear there is no creeping forward or change in revs. · Driving along there is no clutch slippage. · Overdrive works fine What have I looked at so far? · I have bled and bled the clutch, including holding the bleed valve vertical as in other posts. · I have taken the slack out of the linkage, so there is minimal slop at the pedals and the clutch cylinder. The pedal box has new bushes. · I’ve measured the movement in the rod at the slave cylinder, 17mm which seems ok according to the forums. · I disconnected that rod and checked for ‘slop’ and it feels pretty tight, hanging vertically. · I’ve topped up the gearbox with oil....there is a slight leak but not that much. · When I rebuilt the car I refurbed the master cylinder with new seals. It is a .70” version. What next? I really want to exhaust all possibilities before I take the plunge and take the gearbox out. I am aware of weaknesses inside the clutch, especially the fork pin, and maybe the synchromesh is the problem?. If the forum’s advice points there, so be it, but this is one last try to avoid it! Thanks in advance.....

-

A noise and vibration are developing from the gearbox and overdrive, when I engage OD, the noise and vibration almost disappear. It is more noticeable in higher gears. Any idea wherle to start looking, gearbox or od?

-

Hello After a run I have noticed the gearbox making very odd noises in 1st, 2nd & 3rd. 4th seems fine, clutch, selection & overdrive also ok. Layshaft bearings failing? The box was partially rebuilt 30 years ago to include an overdrive, think the layshaft was changed then - probably a swap from another unit rather than new. Not too sure about this, but at the time the overall condition of the box was considered ok. Don't think it's out of oil. Thanks, Adrian

-

Dear all, as ever, a little guidance from the gurus out there would be immensely appreciated! Problem: CR J type box has been beautifully refurbished and all cheerful BUT…now it and the gearstick are reunited, regularly and randomly I can’t get either 3rd and 4th, or Reverse, or 1st and 2nd. Double declutch: no help, so ? not synchro or clutch. Suspect that the spring and ball at the bottom of the gearstick are slightly out of alignment with the rods so that somehow it can’t ‘find’ one of them every now and again. All thoughts if this diagnosis is right very gratefully received - plus any on how to overcome the problem!

-

Hello guys, I'm playing with a Tr6 gearbox, to convert it to overdrive, using a saloon donor box, as many of you have done previously. My problem is : the mainshaft diameter, where it get in the input shaft needle roller bearing is smaller than the "non overdrive" mainshaft (who's .875" apparently). Is there a sort of sleeve to fit in between ? I was thinking of 145008X, but the one I get from a supplier is far to big Thanks in advance for your help,

-

Hi I have a TR2 with an uprated all synchro gearbox with uprated overdrive currently running 20w/50 oil. That was changed last spring since when I've only done about 600 miles The box has been trouble free until this year when it has become increasingly difficult to change gear when the gearbox is hot. There are no problems when the engine and box are cold but once up to temperature it’s becoming a nuisance I’ve changed the clutch fluid (which had been overlooked) which has improved the gear change but the problem has persisted. Because it improved, it might point to clutch issues but the engagement point on the pedal travel doesn’t seem to change with temperature and there are no signs of fluid loss (hard to tell round the slave cylinder because of the ever present oil drips but the fluid level doesn’t drop). The clutch is a TR6 cover and plate on a TR4A aluminium flywheel Next thoughts are to change the oil for say Millers EP 80w90 Any ideas?

-

I have an issue with 2nd gear, changing from 1st to 2nd produces a lovely grating sound every time, it is no better when the car is hot, gearbox oil was changed about 3 months ago when I fitted a new Laycock clutch. It was also grating before the new clutch and the old clutch still had lots of life in it, it was just really heavy to use. However changing down from 3rd to 2nd never seems to produce the grating noises. I assume it maybe a synchro issue unless someone has any better ideas. I have heard that replacement rings are hard to come by, It is a CR model with Overdrive. Any suggestions for the best route forward (other than changing directing from 1st - 3rd every time would be welcomed and is the work easy enough to do at home?? TIA kc

-

Hi all, I’ve recently found an oil leak coming from a hole on the bellhousing and I can’t figure out what it is from the Haynes manual or info online. The hole looks like a bolt hole minus the bolt. However, it looks a bit larger than the others and has a raised ring surrounding it. Also, there is another, smaller, hole close by on the left which isn’t leaking. Does anyone know what the situation is here? Should something be screwed in? I’ve attached a couple of photos. It’s a 1981 car, 5 speed, 2 litre. Any knowledge, suggestions gratefully received. Thanks all, Ben.

-

- bellhousing

- oil leak

-

(and 3 more)

Tagged with:

-

Hi All, Just purchased a 1971 TR6 - but I am aware that many on here will not appreciated it! It is powered by a BMW M50 2.5 engine with a BMW 5 speed box. I have to say is drives brilliantly and I think the performance suits the car. First job is to work out why the break lights don’t work!

-

Picked up a 1976 Triumph TR7 in central Iowa on Monday. Being new to the Triumph TR7, I tried to back her off of the trailer and put her in reverse and started to let off the clutch. She then made a loud pop and decided to try again maybe holding the gear shifter in thinking she popped out of the gear. Same instance happened, she popped real loud. I decided to put the car in neutral and push her off. 1st gear works as do the others no problem. What could cause that sound of an issue? also a rough idle. She’ll go between 500-1500 Rpms and almost die then jump back up to 1000-1500 then back down. Is that a fuel/carburetor issue? (Also have new fuel in the tank) or would it be the timing of the distributor? thanks

-

I am in the processof removing the engine from my TR3a to deal with a significant leak from rear of the engine. (exact cause yet to be determined). I have noticed that I have a number of small leaks from the gearbox, nothing major but it probably makes sense to deal with them while the engine & box are out of the car. The first is the rear seal that was only replaced last year and is already leaking again - is there a better part out there and how easy is it to remove the rear flange and remove it? The second is from the selector forks - again nothing major but is there a fix? The O rings were replaced last year. Rgds Ian

-

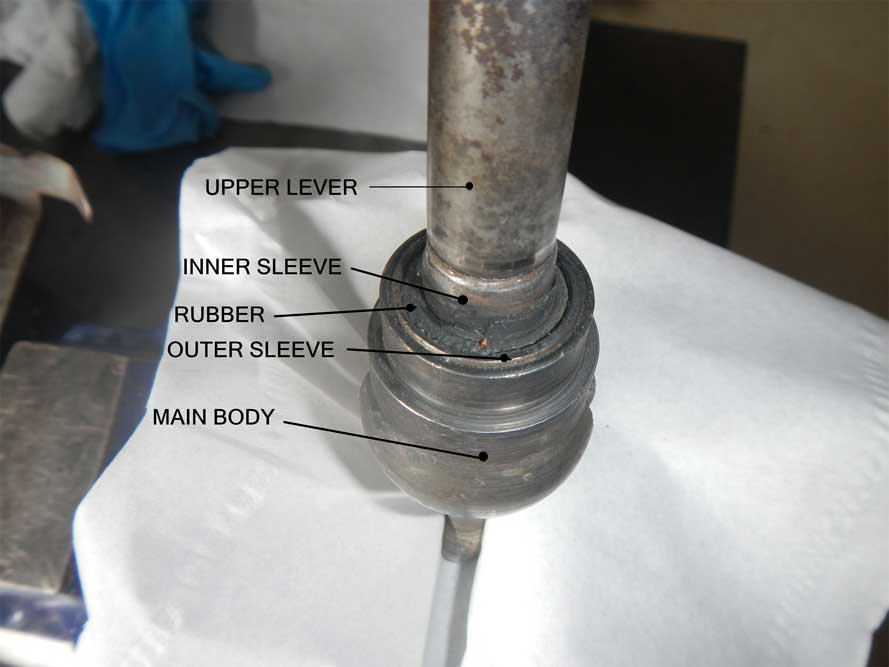

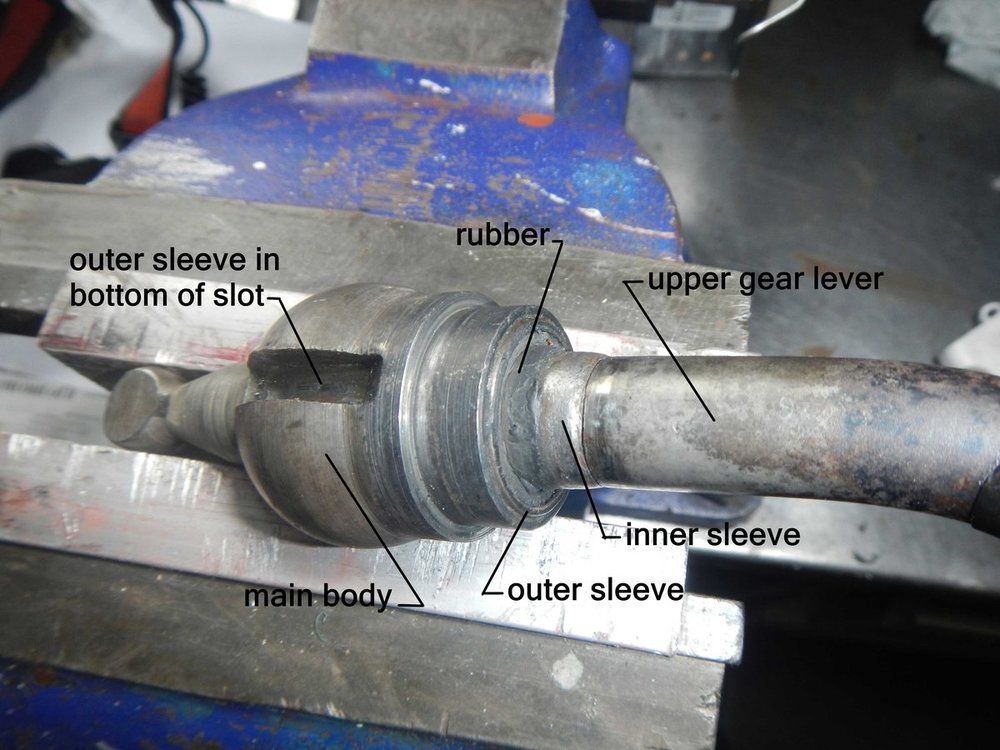

Has anyone attempted to "dismantle" an original gear lever with the rubber "metalastic " bush within the main body of the assembly? I have a lever which I intended to repair the machined groove, in the spherical part of the lever with some weld and then re machine. The problem was how to prevent damage to the rubber vibration damper inside the assembly.On looking at the lever, more closely, it is quite an interesting item. The main lever arm is joined , (how I have not yet sussed) to the inner part of a metalastic bush. the outer of this bush is then pressed into the main body of the assembly which has been bored to take it. The additional complication / cost of this, rather than the solid one piece replacements currently available must have been to reduce the vibration ? noise transmission through the lever. Paul

-

Hi all, I have a question about my gearbox from my TR4 (1962). Does anyone know why my gearbox is harder to switch in hot weather? It's harder to get into gear. Sometimes from three to four a little crack. Not Always. Just that it's not completely synced. In the spring I never had this before. And only if he's been riding hot. The next day everything is back to normal

-

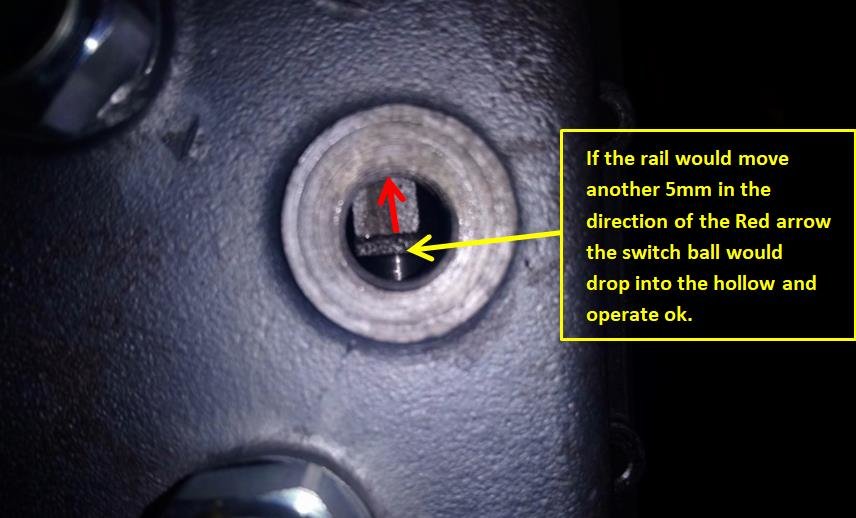

Hi Guy’s I really can’t fathom this one out. And I’ve have had a classic gearbox specialist have a look and no joy. My reverse lights are on all of the time. So I’ve gone back to basics. Not the switch(es), tried 3. Then bench checked them, they all work, spot on. Then checked the wiring is ok. Rev lights work fine when switch connected up but out of GBox and operated by hand. So thought I would try the switch screwed in varying amounts. With the GBox in reverse I’ve screwed the switch in until it just turns the lights on then took it out of reverse. Lights stay on. Then started with it in neutral and screwed the switch in until the lights just come on and then back ¼ of a turn so the light go off. Then put it in reverse and …nothing no lights. So if the switches ae fine and the electrics are fine it must be the GBox not operating the switch correctly. And if I look down the switch hole when in and out of reverse the “high” part which tell the switch to turn on the reverse light is always there. Now the GBox guys says ther is no adjustment in this. But something must be wrong has anyone got any ideas? My radical approach is to get the reverse selector fork, make sure I know which bit is in the way of the switch operating correctly when out of reverse and errr attack it with an Angle Grinder. If I take just the right amount away I think (hope) I can get the light working. But before I take that quite radical action of angle grinding bits inside the gearbox and one got any suggestions what might be wrong cuz it can’t always have been like this surely. Cheers Keith

-

Hi I am looking to replace my (soggy,saggy and perforated) original Gearbox tunnel, there seem to be a number of different materials (plastic or fibreglass) and suppliers. Does anyone have any recommendations? Thanks Rich

- 30 replies

-

Hi Folks, for those wanting to know where the reversing light switch is here is a pic. Roger

-

My local group leader has had a major gearbox failure, it's with a repairer and will cost a good amount to repair due to the amount of parts damaged/required. As he's already got to spend a substantial amount he's wondering if it's worth spending a bit more to do the Mazda 5 speed conversion, I'm hoping to get some experience from members here that I can pass on to him and help him decide which way to go: repair/conversion. Many thanks Gareth

-

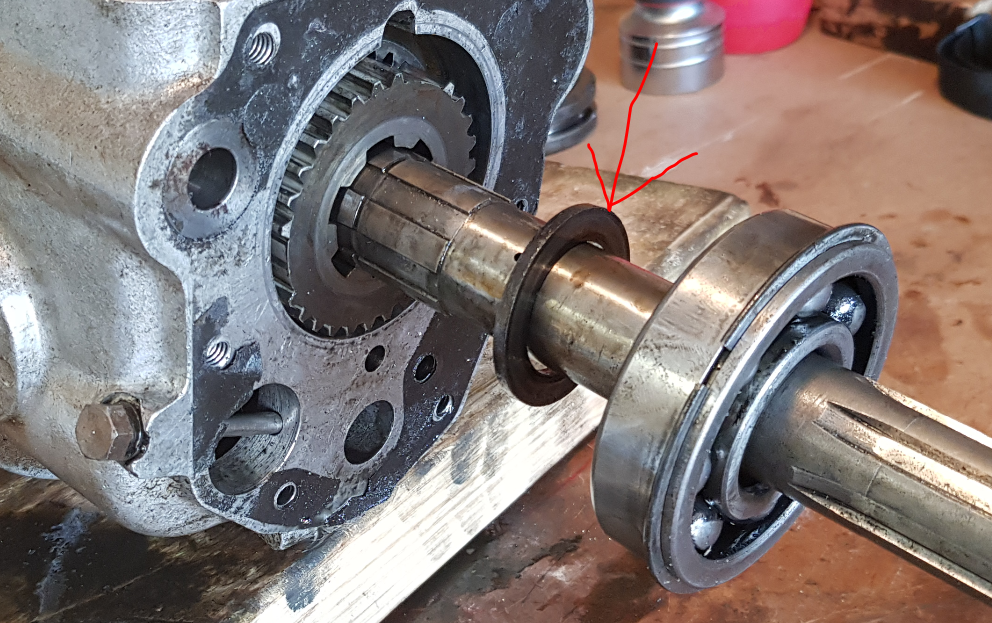

Well - with your help, the gearbox is out and is almost completely stripped down. Already I am somewhat more philosophical about the demise of 1st gear, as it has prompted me to delve into a gearbox for the first time and actually start to learn how the bloody things work... which has led to a few questions... 1. I can't figure out the function of the 'extra' little ball bearing and associated plunger in the 2nd gear synchro hub... it is described in the exploded diagram as being an interlock... my question is, interlocking what, exactly? I think that the 3 springs and ball bearings in the same hub are to hold the outer synchro collar thingo in 'neutral position', but I can't figure out what the interlock ball bearing etc is for. 2. Another query relates to the washer that sits between 1st gear and the big bearing at the rear of the box. The washer I removed is just a plain round washer... not the triangular shaped bearing shown in the exploded diagram (part # 060569). Photo below. 3. Lastly - to replace the clutch fork securing bolt (which snapped off)... am I just as well re-tapping the hole in the fork to accept a metric hi-tensile ss bolt and use that? Only issue I suppose would be drilling a hole for the lock wire... the old threads in the fork seem to have survived my drilling out of the original bolt. TIA!

-

Hi guys Following on from recent chat about gearbox removal... once the box is removed, is it ok to just support the engine using a block of wood between the engine and fire wall (see photo)? I would like to be able to move the car about the garage once the box is removed. I hope that the support under the engine is only really required while there is a chance of the gearbox applying additional load onto the engine (which can happen I presume despite best efforts to support box and engine separately). TIA!

-

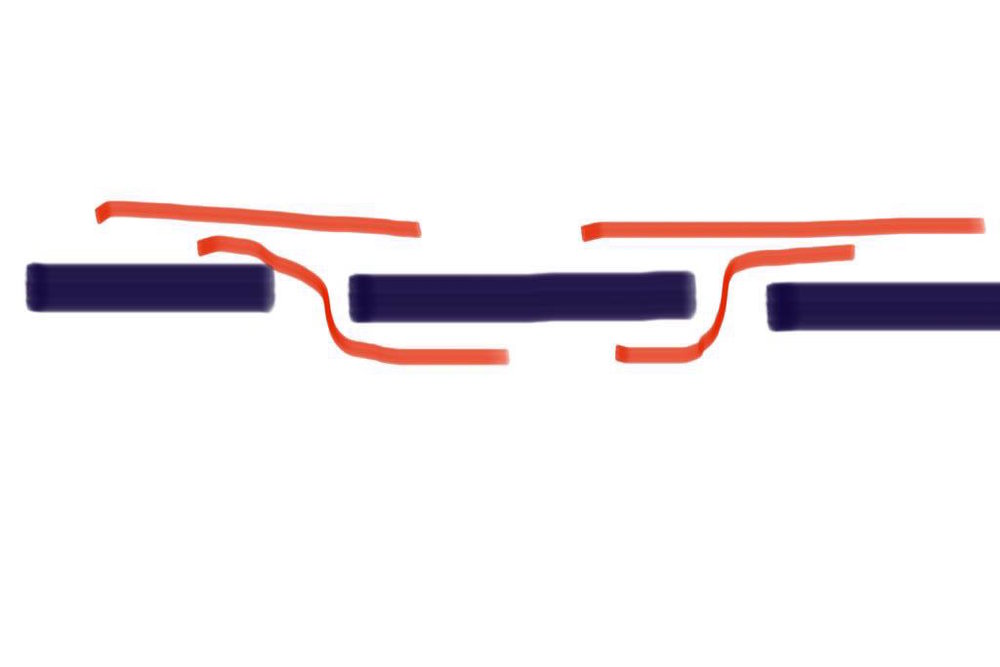

Hello experts! My speedo stopped working last season... The speedo end of the cable was spinning alright but could be stopped by pinching with fingers and so I was looking towards the angle drive (thanks to archive forum post from RogerH). Anyway, I removed the one-piece tunnel today and discovered that the gearbox-facing bayonet fitting on the angle drive was 2 threads/turns loose. All tightened up now and reckon that will be it - any thoughts in advance of my 2 month wait for dry and salt-free roads?? Hopefully I will avoid the need to buy a new smiths angle drive. Also going to take the opportunity to cut in a number of access panels in that pesky plastic tunnel. My plan is to use the cut out piece of plastic and speed tape to form the access panel as per the attached sketch (black = plastic and red = speed tape with the outer of the tunnel on top side of the sketch). That's my initial plan using stuff that's to hand in the garage, but grateful for the benefit of anyone else's experience. Thanks David

-

EDIT... I originally thought it was a half shaft failure... turns out it is gearbox related. Grinding in 1st gear and reverse with very little drive. 2nd/ 3rd / 4th all ok with or without o/d. Looking for diagnosis while I start the process of removing the box and engine... at least this will give me a chance to fix that oil leak and a few other things. Original post: What a shame - just after thinking how well the car was driving and looking (and also consciously thinking how risky it was to be having such thoughts), a half shaft decided enough was enough... at least I hope it was the half shaft! I think I was partly to blame... or fully to blame... I forgot the handbrake was on and then when I took off from the lights, the car pulled away for a split second and then something went pop! I'm trying to re-assure myself that the half shaft should be able to take that sort of load, and so was probably going to break eventually anyway... not sure if that is true or not. Anyway - time to get hands dirty and confirm what's what. Two photos attached are the start of the day, full of promise, and the situation about 1hr later!

-

The attached sound file is a recording of the noise emanating from my gearbox. 1973 TR6 with J type O/D. I have owned the car since 1979. Taken off the road in 1982. 68K miles. The clutch and plate are 700 miles old. The thrust bearing squeals slightly and will probably need changing but I don’t suspect that it’s the thrust bearing which is causing this particular noise; however, I’m open to your opinion. The noise is progressively getting worse, hardly noticeable 400 miles ago. The noise occurs in every gear but only occurs when the gearbox is under load and stops when the throttle is eased back and the load released. It also occurs with or without the O/D engaged. I don’t think it’s the gearstick fizzing (I had a Triumph Herald which did that) There’s plenty of the correct grade oil in the box. New UJ’s on the prop shaft (700 miles) I suppose it could be coming from the O/D rather than the gearbox, but again open to ideas. Anyone heard this noise or any ideas before I remove the box and pull it apart. Many Thanks Ross TR6 Gearbox Noise.m4a